Fastening Fast with Chemical Anchor Studs

When anchoring is installed in high loading and critical situations, the use of chemical anchoring - also known as chemset - is essential.

Threaded rod or rebar is often used, and it is recommended you use a high-quality adhesive to create the chemical bond between the stud and concrete. This ensures that chemical anchor studs, rebar or threaded rod grips the sides of the drilled hole with no pockets of space between irregular features such as the thread or mechanisms.

And it's not just the right products you need. Certification is also essential, so your project's final results are compliant to building-related standards. Chemical anchor studs from Allfasteners are available with complete data and certifications from the manufacturer, so you can tick all the compliance boxes, pre and post-purchase.

Make the Right Choice

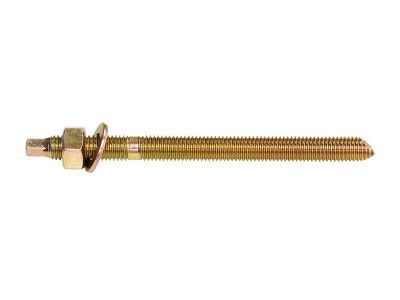

Chemical anchor studs have a high load capacity and are incredibly robust. They are also incredibly adaptable and have a wide range of uses. They are also relatively easy to install.

The chemical anchor studs from Allfasteners are distinct from the typical ones because they are not secured using a customary technique. Because they do not press up against the substrate's surface, there is a much lower possibility of splitting and cracking problems. Instead, a substrate with a unique chemical glue applied serves as the bonding agent for these anchor studs. This resin solidifies around the anchor stud, providing a stronghold for the fastening.

Please get in touch with Allfasteners if you would like more information on our chemical anchor studs. In addition to many other products, our areas of expertise include chemical anchor studs, metric fastener bolts, nuts, washers, screws, rivets, construction fasteners, all-thread, purlin bolts and brackets, and driver bits.

Chemical Stud Types and Applications

Chemical anchor studs have many uses, such as fastening heavy things to masonry or concrete, setting up railings and handrails, hanging light fixtures from above, stabilising machinery, and fastening steel beams to concrete.

Anodising, phosphate or black oxide coating, chrome galvanising, and plating with gold, nickel, silver, tin, zinc, or zinc chromate are some of the finishes for anchor studs. Here are some of its common types and applications.

Aluminum

Aluminum has excellent electrical and thermal conductivity, high reflectivity, ductility, malleability, trivalentity, and oxidation resistance.

Brass

Brass is a metal with moderate strength, suitable high-temperature and low-temperature ductility, good conductivity, outstanding corrosion resistance, good bearing qualities, and low magnetic permeability.

Bronze

Copper is the primary alloying metal in bronze, with one or more other metals, such as phosphorus, zinc, or tin, contributing to its composition.

Copper

One of the best metallic elements for conducting heat and electricity is copper, a reddish-brown, malleable and ductile substance. Copper is also an excellent corrosion-resistant material.

Titanium

Titanium is robust, lightweight, durable, and resistant to corrosion. Titanium studs have extensive applications in the aerospace and medical fields, including joint replacement.

Steel

The iron that has carbon added to it, up to a maximum of 1.7%, is used to make steel studs since carbon is a necessary alloying element. As fastening materials, various carbon and alloy steel grades have the professionals’ trust. To prevent studs from corroding, some grades need coating. Some, like stainless steel studs, can have high-stress ratings and resist corrosion and chemicals.

Fasteners such as studs have a variety of grades of stainless steel. However, stainless steel's hardening is lower than carbon steel's. As a result, hardened steel is yet another popular option for metal studs.

Enquire Now, for High-Quality Chemical Anchor Studs

Enquiries? Talk to the experts at Allfasteners today.