Powder-Actuated Pins & Charges

Powder-actuated pins are a system component for powder-actuated fastening. This masonry fastening system offers a cost-effective way to fasten fixtures under light-duty, static load circumstances. This system comprises powder charges, powder guns, and specially-made fasteners called powder pins.

You can utilise powder-actuated collated pins to forge robust connections between fixtures and steel or concrete. Powder-actuated fasteners, sometimes called direct fastening, are put in place using a type of nail gun known as a powder gun.

These fasteners are perfect for major construction projects since they drive into the material with precision and speed. When activated, small cartridges create an explosive charge that forces the fastener out of the tool and into the fastened surface materials, which are the power source for powder-actuated tools.

Make the Right Choice

Allfastener’s powder-actuated pins and charges are available in various types for installation purposes. These are an effective and dependable way to put fasteners into steel and concrete materials.

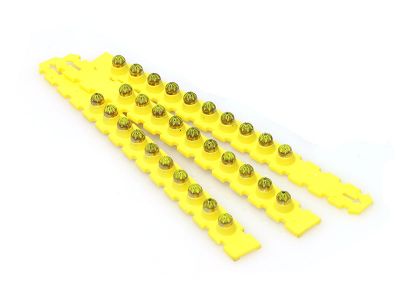

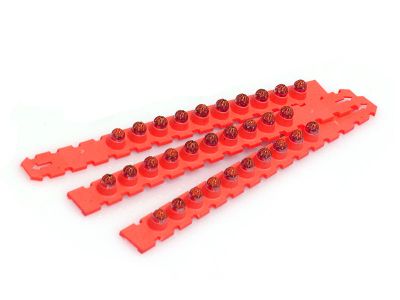

Allfasteners offers a variety of powder-actuated pins and charges for metal framing, electrical or mechanical work, exterior sheathing, insulation, wood framing, walls, and ceilings. Yellow, red, and black 0.27 Calibre Safety Strip Loads are available. Using powder-actuated pins and charges requires knowing the powder load. Yellow has a power rating of 4, red has 5, and black has 7. 10 Shot 0.300" Collated Power Actuated pins and low velocity 0.300” drive pins are also available.

Understanding the colour-coded powder-actuated power load charts is essential before handling these significant and potent tools.

Allfasteners powder loads and tools correspond with tolerances to deliver maximum force within acknowledged national velocity guidelines. The powder-actuated Allfasteners tools come in colour-coded single-shot and 10-shot.

Applications of Powder-Actuated Pins and Charges

For use in steel, brick, concrete, and block applications, high-quality powder-actuated pins and charges offer dependable and consistent performance. You can ensure the best outcomes by selecting the appropriate powder pins and charges. Here are the two major applications of powder-actuated pins and charges.

Fastening to Concrete

One of the applications of powder-actuated pins and charges is fastening materials to concrete. As the fastener penetrates the concrete, it produces high heat and pressure. In addition to protecting tools, this forms a bond with concrete with high loading strength.

Concrete around the embedded area of the fastener shank is displaced when you press a powder-actuated fastener into it. It compresses the concrete immediately surrounding the fastening, which forces it back against the fastener's shank.

Furthermore, heat from the driving action causes the concrete's particles to fuse to the fastener's shank. The fastener is placed in the concrete base material by compression and fusion. The process of riveting into block masonry is the same.

Fastening to Steel

Fastening material to steel is another purpose of powder-actuated pins and charges. Steel's tenacity gives the fastener a clamping effect. It produces a welding and clamping action to provide maximum gripping force and intense heat.

Steel is rotated 360 degrees around the fastener's shank when you force a powder-actuated pin into it. Steel is an elastic material. Therefore, it presses back on the shank to hold the fastener in place. As the fastener shank diameter increases, the load capacity will typically rise as well, as long as the steel thickness is adequate to support the fastener.

Specific fasteners with a knurled shank enable the steel to form a key lock into the grooves, resulting in larger capacities than those achieved with a smooth shank, improving fastening performance in steel even further.

Safe Handling of Powder-Actuated Pins and Charges

The basic parameters for base material thickness, as well as edge and spacing, for secure handling of powder-actuated pins and charges, are as follows:

For Concrete

Edge: Attach no more than three inches from the concrete's edge. The fastener could ricochet and fail to hold if the concrete fractures.

Spacing: Concrete might crack if you put fasteners too closely together. Three (3) inches is the minimum required spacing between fasteners. To avoid the second fastener ricocheting off the first fastener, never apply a fastener too close to another already entered.

For Steel

Edge: A fastener should be spaced 1/2 inch from the steel edge while doing so. When you fire the pin less than half an inch from the edge of a steel base material, the steel could bend or break, causing the fastener to ricochet and seriously cause injury and further be fatal.

Spacing: One inch should be the bare minimum between fastenings. To avoid the second fastener ricocheting off the first, never try to fasten something too close to another fastener on the surface.