Industrial Integrity: Where Precision Prevails

Allfasteners’ Capabilities During Critical Maintenance

The real backbone isn’t always the big machines but the small components that keep them all together. Allfasteners leads in this essential area with its specialised production of durable fasteners and stud bolts designed for tough environments. Recognising the challenges of maintenance shutdowns, Allfasteners positions itself as a crucial partner through swift manufacturing.

The Challenge of Shutdowns

Shutdown challenges, from missing parts to equipment failures, accelerate financial losses by disrupting production and inflating costs. Extended downtime triggers a cascade of financial setbacks, disrupts production schedules, and hits profitability hard.

Aware of these stakes, operators leverage every available tool to prevent such scenarios. Yet, when operations grind to a stop due to the absence of critical components, the role of dependable suppliers becomes paramount. In such critical times, the value of dependable suppliers like Allfasteners skyrockets.

From Manufacturing to Delivery

Allfasteners’ success stems from its comprehensive approach, covering raw stock manufacturing to specialised coatings for harsh environments. This includes producing stud bolts that meet the needs of the heavy industry, as outlined in our case studies.

Case Studies: Demonstrating Excellence in Action

Viva Energy, Major Turnaround

660D, B16, B7 Stud Assembly

A testament to Allfasteners’ capability to mewet demanding project requirements is the major turnaround at Viva Energy in Geelong. Faced with the need for a variety of specialised stud bolts, including long lead items and large diameter assemblies, the project benefited from Allfasteners’ ability to manufacture and deliver within a critical timeframe. This ensured that maintenance proceeded smoothly without extending downtime beyond the planned schedule.

Yara Pilbara Fast Turnaround

B7 Stud Assembly 1-3/4 and 1-1/2

The Yara Pilbara project last year showcased Allfasteners’ agility and commitment to meeting client needs under tight deadlines. Large packages of fasteners were manufactured and imported from Korea within a 4-5 week period, with specially manufactured items being expedited directly from Allfasteners’ manufacturing facilities to the site. The use of Hot Shot Express Delivery services underscored the company’s dedication to on-time delivery, demonstrating how logistical excellence can be a game-changer in maintaining project timelines.

Jadestone Montara Oil Platform and Tank

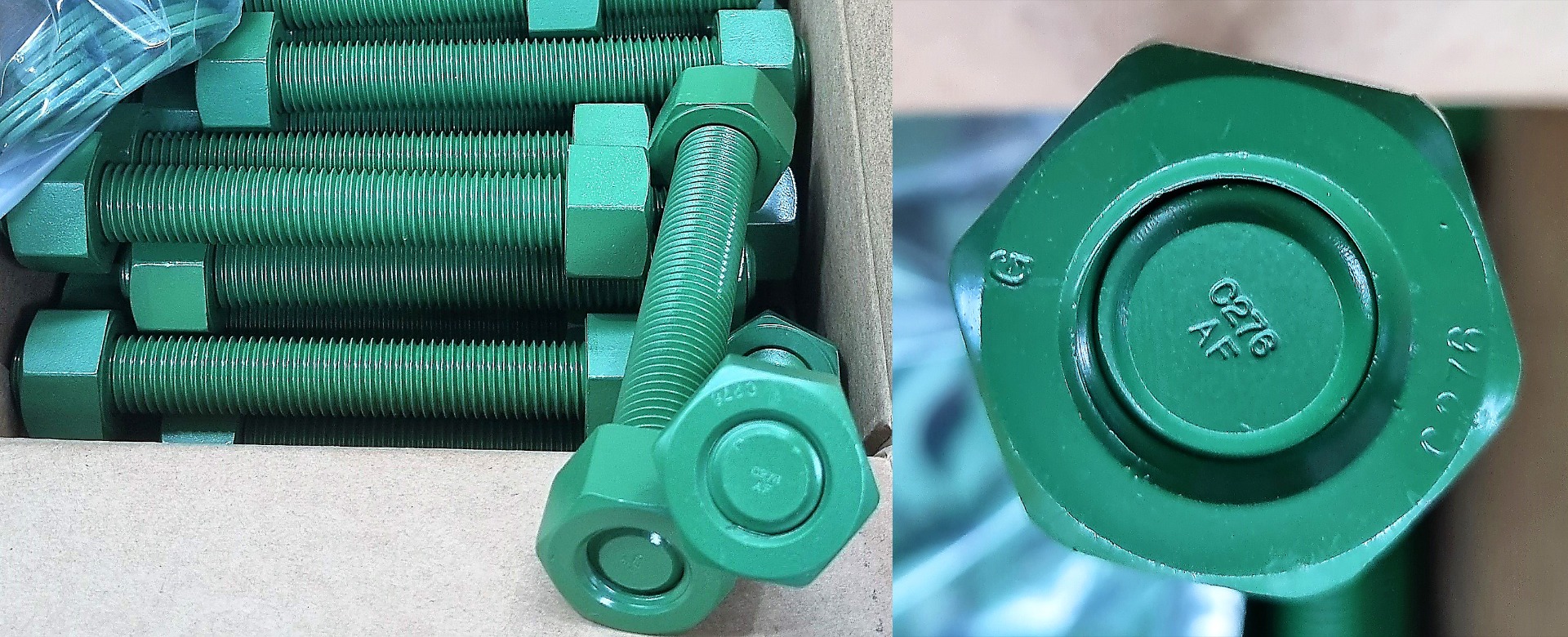

ZincXylan Nickel Alloy Stud Assembly

At the Jadestone Montara project, the challenge was not just about delivering standard fasteners but providing solutions that met specific environmental and material requirements. Allfasteners supplied a large quantity of zinc Xylan studs, with some made from Super Duplex and hex head bolts and nuts with Xylan coating. This project highlighted Allfasteners’ expertise in delivering customised solutions that meet stringent specifications and environmental considerations.

Empowering Your Projects

Driven by the challenges and complexities of these outlined projects, we thrive on delivering innovative solutions that energise us to push the boundaries of what’s possible in manufacturing high-quality industrial fasteners.

Each case study across the industrial sector spectrum showcases how we excel as a supplier and advisor, leveraging extensive knowledge across various application environments and challenges. Our ability to provide custom advice and solutions directly addresses each client’s unique needs – and is part of our solutions-based approach:

A comprehensive range of engineered anchoring and fastening products for projects of any scale, backed by a commitment to innovation, compliance, and the highest standards of safety and quality.

If downtime spells disaster for your project and you value high-quality fasteners, consider us when you’re in a pinch.