T-Bolts and Hardware for Cast-In Anchor Channels | NexCast™

Anchor Channel T-Bolts Engineered for Certified Performance

T-bolts are a critical component of any cast-in anchor channel system, directly influencing load performance, adjustability, and compliance. The NexCast™ T-bolt and hardware range has been engineered to integrate seamlessly with NexCast™ anchor channels, ensuring reliable performance across structural, architectural, and industrial applications.

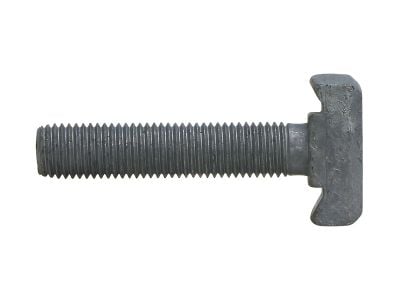

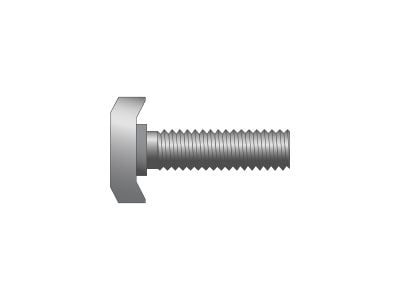

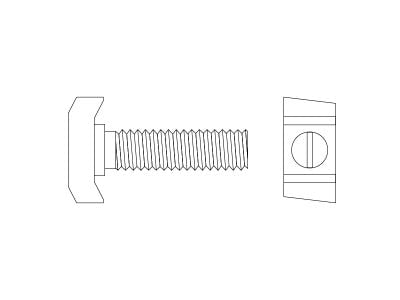

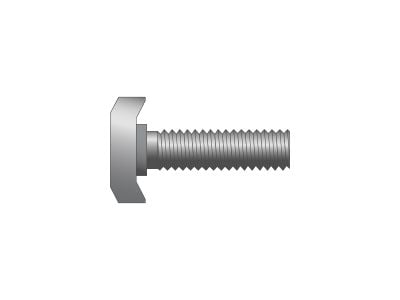

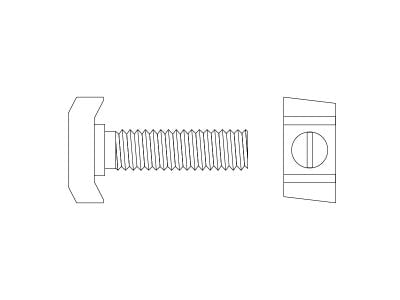

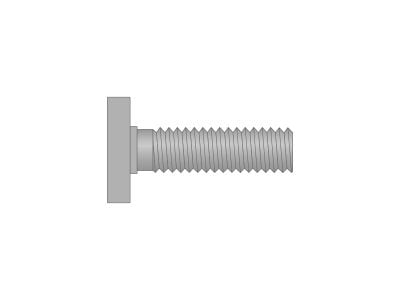

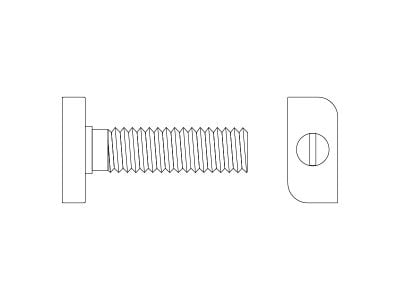

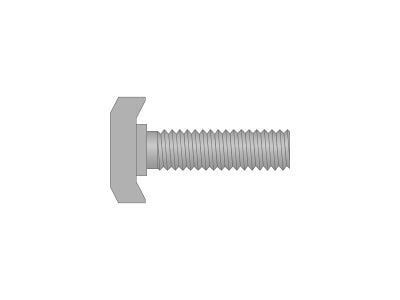

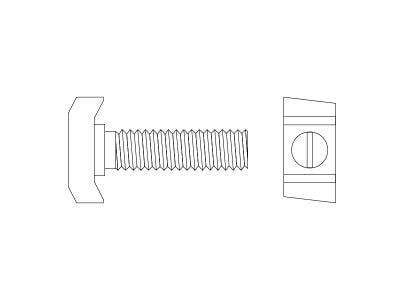

Available in hot-dip galvanised class 8.8 steel and 316 (A4-70) stainless steel, NexCast™ T-bolts are offered in multiple head designs—including hammered-head, hook-head, notched, and toothed variants—covering thread sizes from M8 to M30, depending on channel profile.

Matching T-Bolts to Anchor Channel Profiles

Correct T-bolt selection is essential to achieve the certified load values published in ETA documentation. NexCast™ T-bolts are matched to specific channel types based on material, geometry, and loading requirements:

- Standard galvanised anchor channels are compatible with hammered-head, hook-head, and notched T-bolts in hot-dip galvanised class 8.8 steel.

- Stainless steel anchor channels require 316 (A4-70) stainless steel T-bolts to maintain corrosion resistance and system integrity.

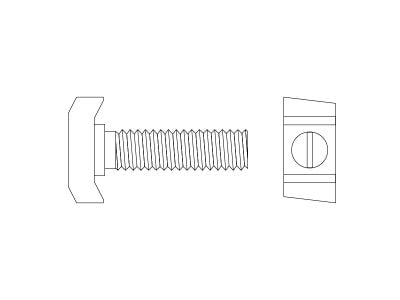

- Toothed anchor channel systems must be used with matching toothed T-bolts to provide mechanical interlock and certified 3D load transfer.

T-Bolts for Powered and Dynamic Load Applications

Only Powered anchor channel profiles are approved for dynamic (fatigue) loading applications. These profiles must be used exclusively with the corresponding hammered-head T-bolts to maintain fatigue certification:

- Hot-dip galvanised Powered channels are compatible only with TB1-G T-bolts in M12 and M16.

- Stainless steel Powered channels are compatible only with TB1-S T-bolts in M12.

This controlled compatibility ensures safe performance in safety-critical environments such as tunnels, transport infrastructure, industrial installations, and high-load façade systems.

Complete Fixing Solutions for Anchor Channel Systems

NexCast™ T-bolts and hardware are designed to support fast, adjustable installation without on-site drilling. Combined with pre-installed cast-in anchor channels, the system enables accurate alignment, efficient construction workflows, and dependable long-term performance.

To ensure compliance with design approvals and standards, NexCast™ recommends always specifying anchor channels and T-bolts as a complete system.

Need help selecting the correct T-bolt?

Download the NexCast™ technical documentation for compatibility tables and load data, or contact our technical team for application-specific guidance.