Big Impact in the Big Build

Wedge Anchors in Victoria Metro

The state of Victoria in Australia is one of the most populated states in the country. However, the population density is much higher in Melbourne largely due to the state’s population residing mostly within 10,000 square kilometres.

The city has a population of over 5 million people while the state has a population of just over 6.5 million people. It is projected that the state’s population will reach 10 million by 2051.

To accommodate this population growth, the State Government has launched “Victoria’s Big Build”. An infrastructure project that includes 165 major road and rail projects with a total value of $90 billion. These projects range from tunnels and metros to freeways requiring massive amounts of construction materials from concrete to steel to fasteners to bring it all together.

Allfasteners is proud to be a part of Victoria’s Big Build, having supplied specialised bolting along with everyday fixings to many of these projects, including a recent solution for one of the many tunnels being built across the city.

With the scale of projects increasing in size and complexity, there are many and varied requirements for these large infrastructure builds, meeting lead times and providing compliant products is key.

Tunnel Vision

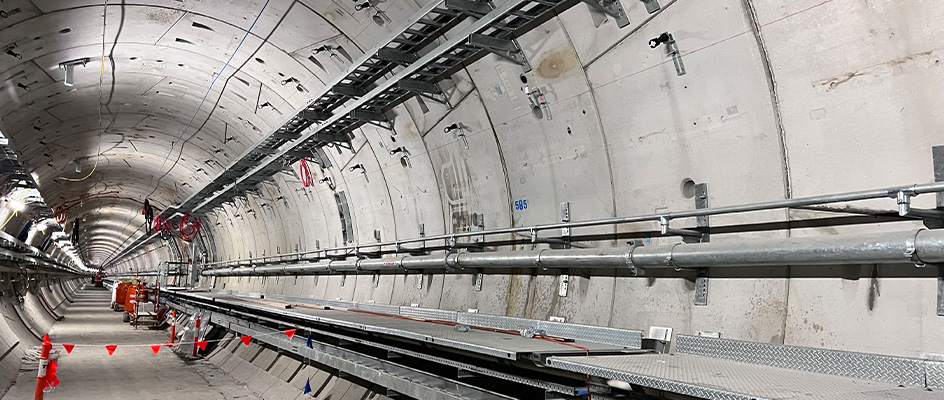

The client required an engineered stainless steel anchor to install support columns for drainage pipes and had a very tight lead time. Due to long lead times and budgetary issues, the specified anchors could not be sourced that were recommended during design. They risked project delays and budget blowouts if a replacement wasn’t found in time.

They decided to look for an alternative anchor that had to meet load requirements, corrosion resistance, and specified 100-year design life. With many of the tunnel project engineers having worked with Allfasteners before, they knew exactly who to get in contact with.

With a reputation for delivering products that are ETA certified and can be delivered with tight lead times, the client sought help from Allfasteners engineering team. The engineering team rapidly responded and recommended a similar product that would meet the requirements while staying within the budget and timeline.

The NCC compliant WA-S1 wedge anchors were recommended for their stainless steel construction and load-bearing capacity in critical settings. Made from 316 (A4) stainless steel, characteristically suited for external conditions in coastal or industrial environments, they were a perfect fit for the requirement to install drainage support systems in the tunnel.

As a commonly stocked product in the Allfasteners range, the anchors could be shipped quickly to site without delaying the project. The last piece before engaging was compliance approval.

Compliance Conundrums

Respecifying anchors after the design phase can be a compliance nightmare. If the new products don’t meet the original design intent, it can cause headaches for builders, engineers, and certifiers. With time already pushed to the limit, the client was keen to avoid any delays.

However, Allfasteners range of NCC compliant anchors meet a range of testing criteria, including European Technical Assessments deeming them compliant with AS 5216 standard. As part of a design change, rigorous checks are conducted involving independent engineering assessments and consultation, following this, the WA-S1 anchors were approved for use. In addition, we provided the required 100-year design life certification. The tunnel client was able to anchor their drainage supports with the WA-S1 wedge anchor, keeping the project on track, to schedule, and under budget.

Light At The End - Project Success

Allfasteners has a long history of supplying bolts, screws, and washers for major infrastructure projects. With a strong reputation for delivering products that are compliant to Australian Standards and can be delivered with tight lead times, the supplier is often relied upon for critical projects. And the result was a resounding success for all parties involved.

With a proven track record in the industry and in the tunnel project, Allfasteners was sourced as a complete fastener solution for the project with products such as concrete screw anchors, isolation washers, and custom fabricated hold-down bolt assemblies.

Projects of this size are always faced with many challenges, but with the help of Allfasteners, they can be overcome. With a commitment to quality products and customer service, we will continue to play a part in Victoria’s Big Build.