Polyurethane vs Polymer Sealant

Get a Grip the Right Way

Silicone. Polyurethane. They are almost the ‘Hoover’s of the sealant world, synonymous with anything that seals or even adheres, no matter what the substrate or conditions are.

Actual silicone and polyurethane-based sealants and adhesives have lived on unquestioned by trades for decades as the default solution for filling joints, achieving watertightness and finishing-off construction projects. And in construction, there’s a real “if it ain’t broke, don’t fix it” rule, so getting innovative products across the line with tradies, like polymer adhesives and sealants, can be a long term proposition. There are, however, some fundamental reasons why you should come across to the polymer side.

Safety – an Environmental and Personal Concern

Polyurethanes—and a handful of coloured silicones—contain isocyanate as a curing agent. Polymer-based sealants and adhesives do not. Isocyanate can cause occupational asthma, skin irritation such as dermatitis, irritation to the mucus membranes, eyes, nose and throat, as well as gastrointestinal irritation, chemical bronchitis and pneumonitis. It doesn’t take much more evidence to realise that this sort of danger can jeopardise compliance with OH&S regulations let alone the welfare of contractors. Polymer-based silicones, sealants and adhesives are also solvent-free, making the use of them onsite far better for the environment, especially where rain encourages run off.

Multi-Substrate Cohesion

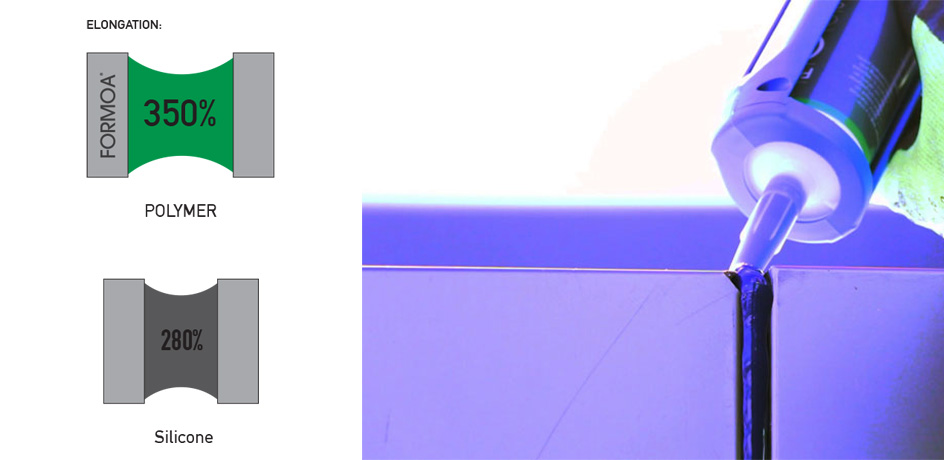

Again, standard silicone has been seen as the use-for-all adhesive by many for a long time. But polymer adhesives have a far greater cohesion strength, and will adhere to far more types of surfaces and substrates, including composite, GRP, polycoated steel, concrete, masonry, and rigid and flexible EPDM/PVC. And some polymer adhesives also double as a sealant. In this category, there are some impressive numbers in regards to strength and durability. For example, with polymer, the elongation at break point can stretch up to 350% whereas many silicone alternatives may only stretch to around 280%. And the polymer option will remain cohered to both substrates. This is obviously important in a scenario where the substrates filled are susceptible to drastic expansion and contraction.

A Continuum of Durability

The other advantage of polymer compared to silicone is advanced durability, the most notable is hardness. For example, a silicone-based adhesive like Tremsil 890 has a Shore A rating of 24. Compare that with a polymer adhesive sealant such as Formoa 010 Colours with a Shore A rating of a whopping 40—can be up to 45 in some conditions—and you have not only a sealant but a virtual substrate within a substrate that can withstand high external forces and climactic conditions.

Workability in Finish and Design

One challenge with working with silicones can be trying to make it finish well – airborne particles getting stuck in the silicone before its cured, bubbling, and a limited choice of paint types—namely enamel—with which to cover it. And if you are fortunate enough to find a coloured silicone, the range of colours if often limited. With more advanced polymer adhesive sealants, the colour range can be almost infinite; even custom colours are available through some manufacturers.

During curing, polymer does not attract or catch dirt or any other kind of particle. Nor does it bubble, resulting in a completely smooth finish with maximum paintability, if desired, with water-based paint. This again bolsters polymer as the choice for increasing the health and safety of the user.

Formoa 010 enquiries from the USA or Canada? Get in touch with your national branch here.