AFI 24 Trucks-Worth for the Earth: AF INDUSTRIAL Holding Up White Rock

White Rock Wind Farm, the $400 million, 199 turbine development that will eventually provide green energy to 75,000 homes, is a project initiated by Goldwind Australia, a subsidiary of Chinese organisation China Energy Conservation and Environmental Protection (CECEP) Wind Power. This, and the support provided by the Australian Government Renewal Energy Target legislation, has the made the project possible and is creating opportunities for many Australian contractors and skilled trades.

The Challenge

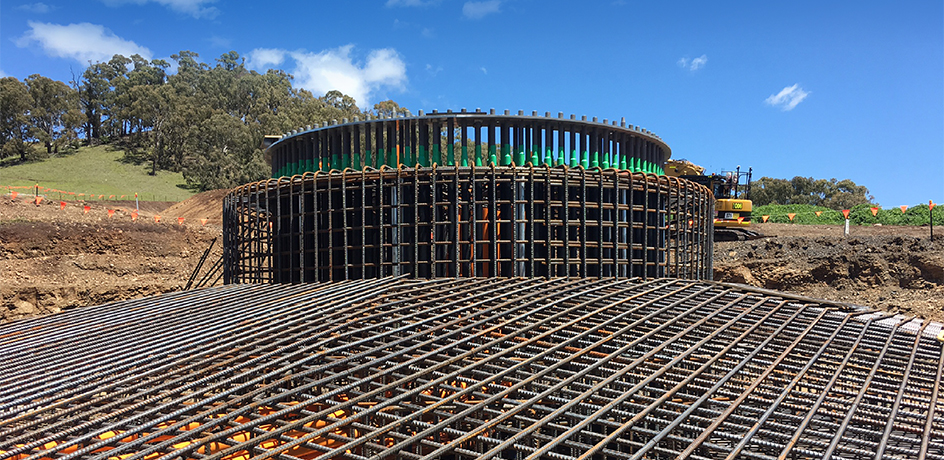

Put simply, the client needed reliable supply hold down products, and fast, without engaging in several suppliers for different products. Working in close consultation with White Rock’s engineers, AF Industrial were commissioned to manufacture and supply foundation bolts, pipe sleeves, split rings and various structural-grade fasteners to be included in the hold down bolt assembly, making a secure and stable footing for the turbine towers.

The Solution

And the job has been no small feat. In total, AF Industrial provided 536 tonnes of componentry, shipped from Sydney on 24 semi-trailer trucks. Jim Strange, AFI director, is pleased with being involved in the project.

“Before our involvement, this project had created a lot of buzz in the media. So of course, we’re only too pleased to be involved,” said Jim. “And to be able to blend our expertise with that of White Rock’s technicians and engineers is very exciting. It’s a great feeling to be involved in something that is not only a record-sized development for New South Wales, but also something that will make a difference to the lives of so many, as well as the environment.”

AF Industrial helped White Rock adhere to their completion schedule through consultation and supply of componentry for additional infrastructure.

"White Rock now sees us as a trusted and reliable partner with fast-turnaround lead times for customised structural components and fasteners."

The Result

“We have set up a relationship now,” says Jim Strange, “considering we had the first semi-trailer load on site within six weeks of the signed contract, White Rock now sees us as a trusted and reliable partner with fast-turnaround lead times for customised structural components and fasteners. Should CECEP continue with more clean energy projects in Australia, we look forward to working with them.”