Site Testing of Anchors

Site testing of concrete anchors may be required for one of two reasons:

- Verification of correct installation (proof tests)

- Determining the strength in a substrate where performance data is not available (ultimate tests)

Testing of anchors in concrete is generally not necessary as performance is well known and is covered by AS 5216 and the corresponding product specific European Technical Assessment (ETA).

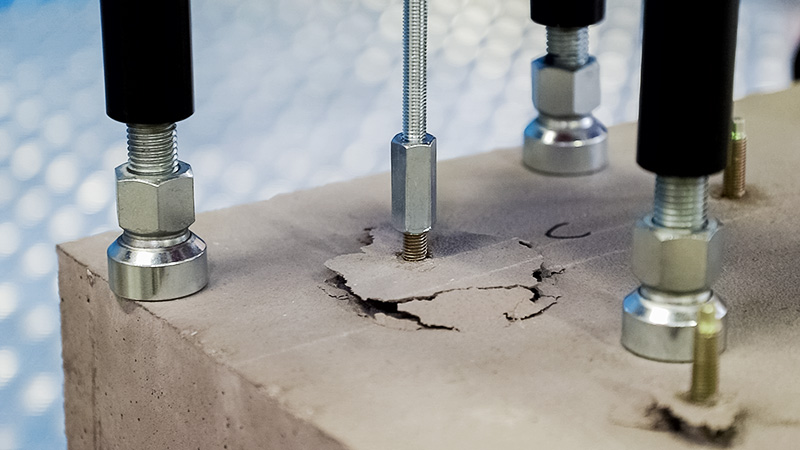

Tensile testing is best to determine correct installation or anchor suitably. Shear strength testing is usually not required because it is less sensitive to poor installation and is dependent on the substrate strength and edge distance. Allfasteners has the capability to do both tension and shear testing onsite.

This topic is not coved by Australian Standards. However, Australian Engineered Fasteners and Anchors Council (AEFAC) technical notes provide guidance on this. Please refer to AEFAC TN 05 – Guidelines for Site Testing of Anchors, Volume 1 to Volume 4 for detailed information. These are available on AEFAC’s website. Information in this chapter is a summary of a few main points with some additional practical recommendations from Allfasteners.

Proof Tests

If it is deemed necessary to verify correct installation, proof tests are conducted on a sample of project’s anchors. The test load (proof load) is to be determined by the responsible engineer and is project dependent. The maximum test load should not exceed both of the following to avoid damage:

1. 0.75 x ULS design capacity (design characteristic strength) of the anchor

2. 0.7 x characteristic yield capacity of the steel

If the design loading for the specific application is close to the design capacity of the anchor, the proof load can be equal to the design load. If the loading is quite low and the engineer just wants to get a general indication of correct installation, the proof load can be equal to the Working Load Limit capacity (WLL) of the anchor. The WLL can be estimated by dividing the design capacity by 2.0. In any case, the proof load should be at least equal to the design load applied to the anchor while not exceeding the abovementioned limits.

The proof load should be maintained for minimum 30 seconds and should not drop more than 10% in that duration.

A minimum of 3 anchors or 2.5% of the total relevant anchor population, whichever is greater, is recommended to be tested. In some cases, such as fall arrest systems, 100% of anchors may need to be tested. AEFAC TN 05 – Volume 2 provides further guidance on this.

Ultimate Tests

These are required to determine anchor strength. Some examples when these are needed include: into unknown substrate such as masonry that is not coved by an ETA, smaller edge distance than tested in the ETA, or if the anchor does not have published performance data. All these are subject to the manufacturer provisionally approving the anchor as suitable for the application of interest. Please note that performing these tests would not make the anchor AS 5216 compliant, but just provide reassurance of adequate performance. The anchors for these tests are sacrificial and should not be used in the project.

A simplified conservative approach is to test minimum 5 anchors to failure, taking the weakest value and applying a factor of safety of 3.1 to determine the Working Load Limit capacity (WLL) which then can be compared with the unfactored design load. This test does not have to be done to failure if all anchors meet 3.0 x unfactored design load. For nylon anchors the factor of safety needs to be 5.1 or 5.0 following the same method. These are just recommendations, and the engineer may elect a more conservative approach. AEFAC TN 05 – Volume 3 provides further information, and guidance on less conservative methods as well.

The test load should be applied gradually where the peak load is experienced 2 to 3 minutes from the start of the test.

Masonry

Design and testing of anchors in masonry is not currently covered by Australian Standards. AEFAC TN 05 – Volume 4 provides guidance on anchor testing in masonry.

Allfasteners recommends a minimum factor of safety of 3.0 when determining the Working Load Limit capacity (WLL). Common practice in United States is to use a factor of safety of 5.0 if based on site ultimate testing.

Testing Equipment

Typical testing equipment includes a hydraulic cell and a tripod. A tripod is necessary to ensure that concrete failure is tested as well, not just anchor pull-out.

Safety Hint: When testing anchors, it is not recommended to exceed the steel failure load of the anchor. Sudden steel failure may lead to equipment damage or danger to personnel.

IMAGE: Shear test of chemical anchor VF22PRO+ and stud, onsite using Hydrajaws M2050 portable tester.