Cast-In Anchor Channels — ETA Certified & AS 5216 Ready

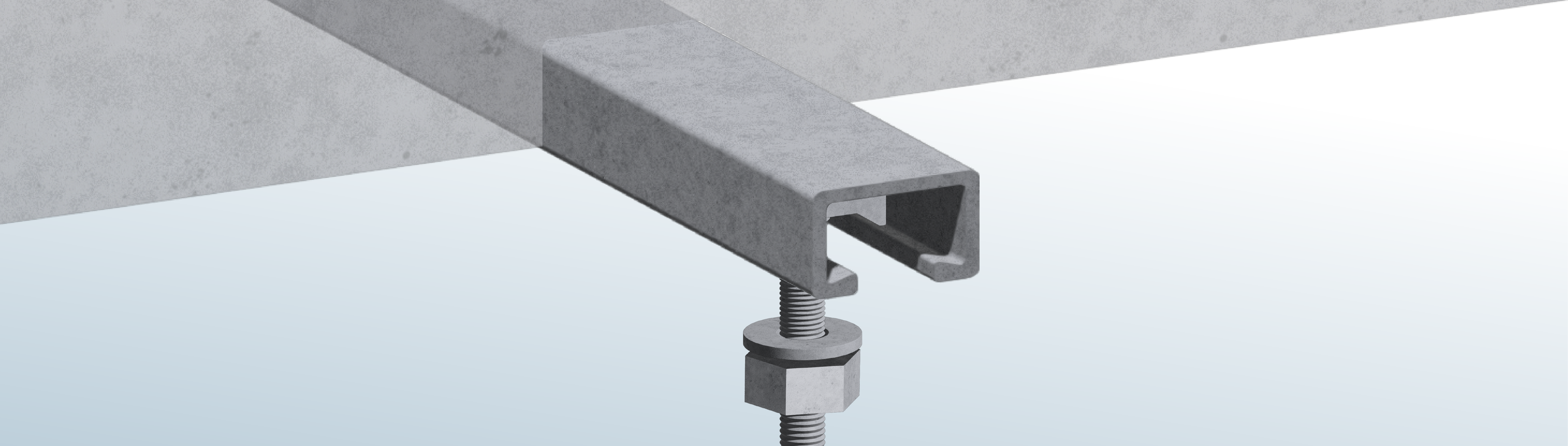

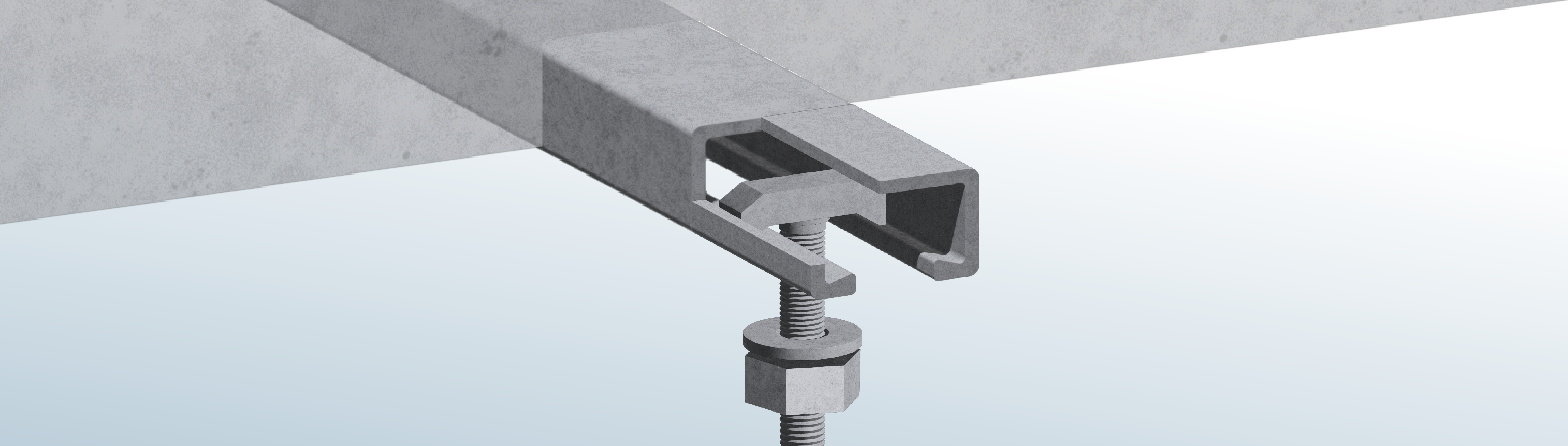

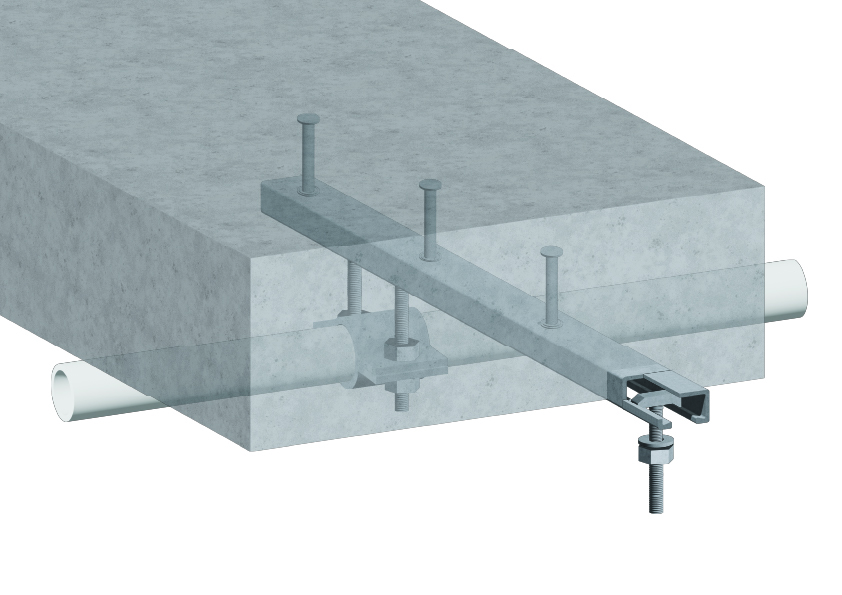

Cast-in anchor channel systems have become a preferred solution for engineers, contractors, and concrete manufacturers seeking greater control, consistency, and compliance in structural fixings. Unlike post-installed anchors, which require on-site drilling, layout precision, and can introduce structural risk, cast-in channels are pre-positioned in the formwork or precast unit — ensuring the correct alignment, load path, and edge distances every time.

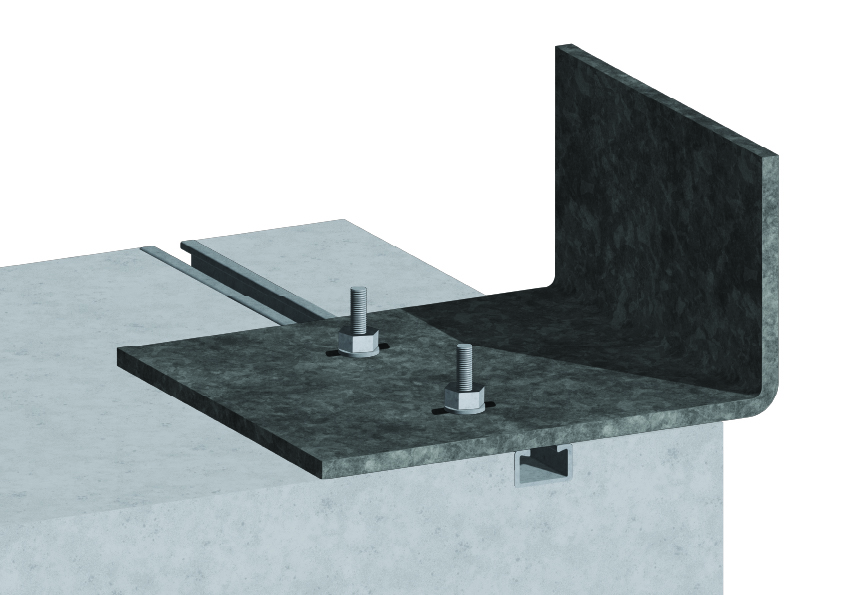

This system dramatically reduces rework and installation time, especially in applications where accuracy is critical. In high-profile façade and curtain wall installations, where bracket positions must align precisely with external cladding or glazing systems, the adjustability of cast-in channels provides much-needed flexibility and assurance. For precast manufacturers, anchor channels streamline the factory process, eliminating the need for secondary fixings after concrete is cured.

With growing emphasis on quality assurance, compliance, and construction speed, cast-in anchor channels offer a smarter way forward — making complex concrete connections faster, safer, and structurally sound.

Our systems are ideal for:

- Façade and curtain wall support

- Precast panel connections

- Civil and infrastructure elements

- Service brackets, lift shafts & seismic fixings

Certified Strength — Built for Australian Conditions

We supply a proven range of cast-in anchor channels manufactured in Europe, globally trusted and ETA-certified, now available in Australia.

Key Advantages

- Longer, high-strength pressed studs for superior concrete bonding

- Certified for dynamic loads — seismic, wind and vibration rate

- Fast, no-drill installation with adjustable fixings

- Compliant with AS 5216 via European Technical Assessment

| Channel | Type | Dimensions | Applications |

| 52/34P | Hot Rolled | 52 × 34mm | Heavy precast, infrastructure |

| 50/30P | Hot Rolled | 50 × 30mm | Civil, commercial |

| 40/22P | Hot Rolled | 40 × 22mm | Medium-duty fixings |

| 40/26P | Cold Rolled | 40 × 26mm | Light façades, brackets |

- Compatible T-bolts available (M10–M20)

- Supplied with foam filler and nail plates for easy casting