Screw Gauge Comparison

Screw Size Identification

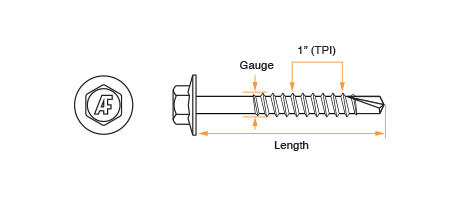

The description of the size of screws is commonly listed as three figures – firstly the gauge, second the threads per inch (TPI) and the third figure is the length either by inches or millimeters (mm).

For example:

|

|

|

Gauge

The gauge of the screw is determined by the basic size of the outer thread diameter (major diameter). As it is quite common to purchase screws using gauge as a measure in Australia we have referenced the metric equivalent here as a guide.

Metric screws have also made their way into the market however these are normally denoted with a M prefix and represent the same outside diameter i.e; M8 = 8mm, M10 = 10mm, etc,.

| Gauge | ||

| Metric Ref. | Inch Ref. Approx | |

| 0g | 1.5mm | 0.060 |

| 1g | 1.9mm | 0.073 |

| 2g | 2.25mm | 3/32" |

| 3g | 2.5mm | 0.099 |

| 4g | 2.85mm | 7/64" |

| 5g | 3.3mm | 1/8" |

| 6g | 3.5mm | 9/64" |

| 7g | 3.9mm | 5/32" |

| 8g | 4.2mm | 11/64" |

| 9g | 4.5mm | 0.177 |

| 10g | 4.8mm | 3/16" |

| 12g | 5.5mm | 7/32" |

| 13g | 6.1mm | 15/64" |

| 14g | 6.3mm | 1/4" |

| 15g | 6.5mm | 1/4" |

| 16g | 6.8mm | 0.268 |

| 18g | 7.5mm | 0.294 |

| 20g | 8.1mm | 0.320 |

| 24g | 9.4mm | 0.372 |

Browse Screws By Type:

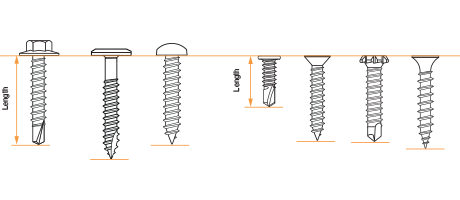

Screw Length

The length of a screw is determined from the point to the underside of the head, this means for any head type that protrudes the surface, the head height is not counted. So for all screw heads that are to be flush with the surface such as a countersunk head the length stated is the full length from the tip of the screw to the top of the head.

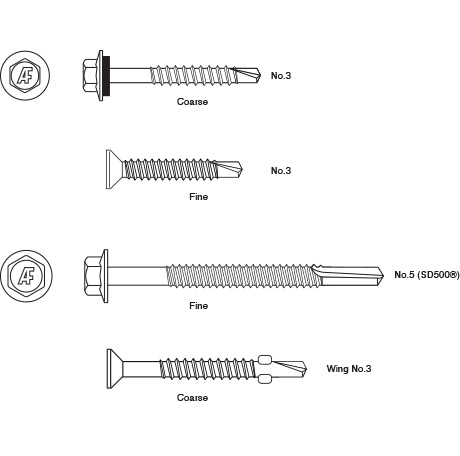

Self Drillers (Metal Teks)

Self drillers (SD) or self drilling screws for metal a.k.a metal teks are made with a drill point similar to a tip of your common jobber drill bit. Without the need to pre-drill using these screws the gauge, TPI and screw tip will determine what thickness of metal can be fixed.

A coarse thread screw is considered as up to 16 TPI and should be used with thin steel up to 2.4mm, alternatively a fine thread screw is anything greater than 16 TPI and can be found on screws for steel up-to 12mm thick.

| Gauge | TPI | Max. Drill Capacity |

| 6g | 20 | 2.3mm |

| 8g | 18 | 2.5mm |

| 10g | 16 | 3.5mm |

| 24 | 4.5mm | |

| 12g | 14 | 4.5mm |

| 24 | 6.0mm | |

| 12g (SD500®) | 24 | 12.0mm |

| 14g (SQ500®) | 10 | 3.0mm |

| 20 | 12.0mm | |

| 8mm (SQ800®) | 20 | 20.0mm |

Common shape for a drill point is a shorter No.3 drill point and for larger screws to drill 6mm and above a longer No.5 drill point is used such as SD500® self drillers. Other types of drill points include winged drill points which as described features wings between the point and threads. These wings aid in boring through timber before hitting metal allowing the head of the screw to pull in flush i.e; in decking or cladding applications.

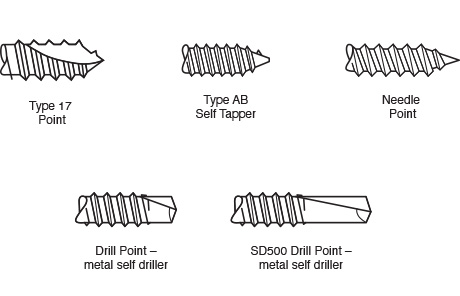

Type 17 Timber Screws (T17)

A self drilling milled point screw tip for timber – the Type 17 tip is found mostly on screws designed for heavy timber construction. The sharp point is also capable of cutting through thin sheet metal if required.

| Gauge | TPI | Min. Embedment |

| 6g | 18 | 20mm |

| 8g | 15 | 20mm |

| 10g | 12 | 25mm |

| 12g | 11 | 30mm |

| 14g | 10 | 35mm |

Self-Tapping Screws (Type AB)

A self tapper features a die produced point and a rolled thread which leave a thread start on the taper. Not to be confused with a self-driller you will need to pre-drill prior to fixing in most applications. The Type AB gets its name from the tapping action it creates in the undersized pre-drilled hole.

| Gauge | Metric Ref | TPI | Pilot Holes | Pre-Drill or Punched Holes* | Drill Capacity |

| Softwood | Metal [min-max] | Metal Thickness [min-max] | |||

| 2g | 2.2mm | 32 | 1.5mm | 1.6 – 1.95mm | 0.45–1.52mm |

| 4g | 2.9mm | 24 | 2.0mm | 2.05 – 2.60mm | 0.45–2.03mm |

| 6g | 3.5mm | 20 | 7/64" (2.8mm) | 2.35 – 3.20mm | 0.45–2.64mm |

| 8g | 4.2mm | 18 | 1/8" (3.2mm) | 2.90 – 3.80mm | 0.71–3.18mm |

| 10g | 4.8mm | 16 | 9/64" (3.6mm) | 3.40 – 4.50mm | 0.71–4.75mm |

| 12g | 5.5mm | 14 | 4.2mm | 4.10 – 5.10mm | 0.71– 4.75mm |

| 14g | 6.3mm | 14 | 4.9mm | 4.80 – 6.00mm | 1.22 – 6.35mm |

*Due to the variety of the hardness of metals and different operating conditions, it may be required to vary these dimensions which should be used only as a guide