Screw Driver Bits – the Differences

The evolution of the Phillips screw driver tip as the most common bit seen today – and when to choose impact driver bits over regular driver bits.

The Slotted Screw Head

The Slotted Screw Head

Until the 20th century, the slotted or ‘blade’ style screw head configuration was the most common design for its ease of production. Fast-forward to the power drill – a revolution in the way one could pre-drill holes in various materials, increasing accessibility for screws to be used. This made way for Henry F. Phillips’ design for the cross-recessed drive type credited to his name – the Phillips® drive (c.1936).

The Phillips® driver was first adopted by screw makers and the automotive industry for its self-centring design in the 1940s. Success came with its use in power tools where a slotted configuration was more likely to make the driver slip out of the screw head, damaging the surrounding surface.

Phillips® driver and all other common head types are readily available as driver bits in a range of sizes and lengths typically distinguished by number such as P2 – these are arbitrary in designation and do not indicate dimension.

Common Driver Bits:

- Phillips® – hugely popular in manufacturing industries. A direct solution that addressed a number of issues associated with slot-driven screws: cam out, difficult centring and alignment with surface, and difficulty with powered tools.

- Square drive – both the tool and screw have a slight taper in the recess. Advantages are the easy insert of the tool, and the screw is often held in place with the square bit itself, without the need for the user to hold it. With less cam-out, a square drive screw can easily be removed, even after having been painted over – square drive screws are popular in decking and timber cladding.

- Hex (socket) – a screw with a hexagonal recess that can be driven in using a hex wrench (Allen or hex key) or a hex bit. Tamper-resistant versions have been made available featuring a centre pin which requires a compatible bit.

- Torx (star drive) – a six-sided star shaped recess drive designed to allow increased torque transfer from the driver to the bit, compared to other systems. It reduces installers’ fatigue by minimising the need to bear down on the power tool to prevent cam-out.

Why do driver bits break?

Tool manufacturers revolutionised portable power tools with the introduction of lithium-ion batteries and brushless motors. These advances now provide greater and more consistent power. The amount of rotational force that impact drills achieve plays an advantage and disadvantage to the user when driving fasteners and screws.

- Advantage – useful for installing long and/or larger gauge screws or anchors in harder materials.

- Disadvantage – can apply excessive torsional stress on driver bits cause them to break and fail.

So why use an impact drill? When longer or bigger gauge screws, which require more torque, are used. Concrete screws, large gauge self-drilling screws into metal, and coach screws into hard woods also benefit from the use of an impact driver. If you are completing fine detail work best to use a drill driver with a variable setting.

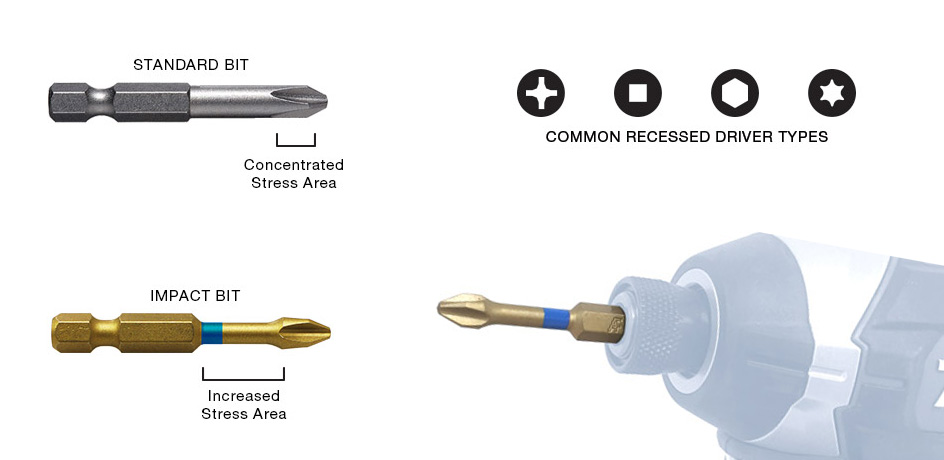

Impact Driver Bits vs. Regular Driver Bits

Ever heard of Ti-N impact driver bits? It’s not just a pretty coating. Ti-N impact driver bits have two main advantages over regular driver bits – a greater torsional strength and a larger breaking angle which gives them greater flexibility and cushioning under impact, increasing their average service life. This is achieved through the shape of its shank and modified tip effectively shifting the excessive stress away from the tip into a greater torsional zone.

- The Ti-N coating increases wear life – deflecting excessive heat caused by the high loading.

- The unique shape increases service life and decreases user fatigue and installtion issues.

- Better for use in high torque applications where standard bits will break.

- Recommend when driving screws with an impact driver.

- Available in P2 Philips bits – 25mm, 50mm and 75mm lengths, and in square, hex, and torx (by request).